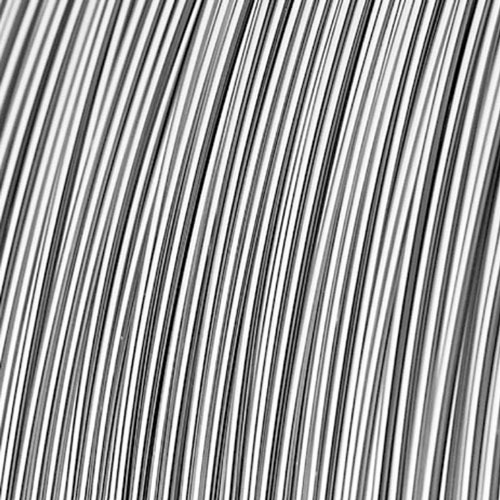

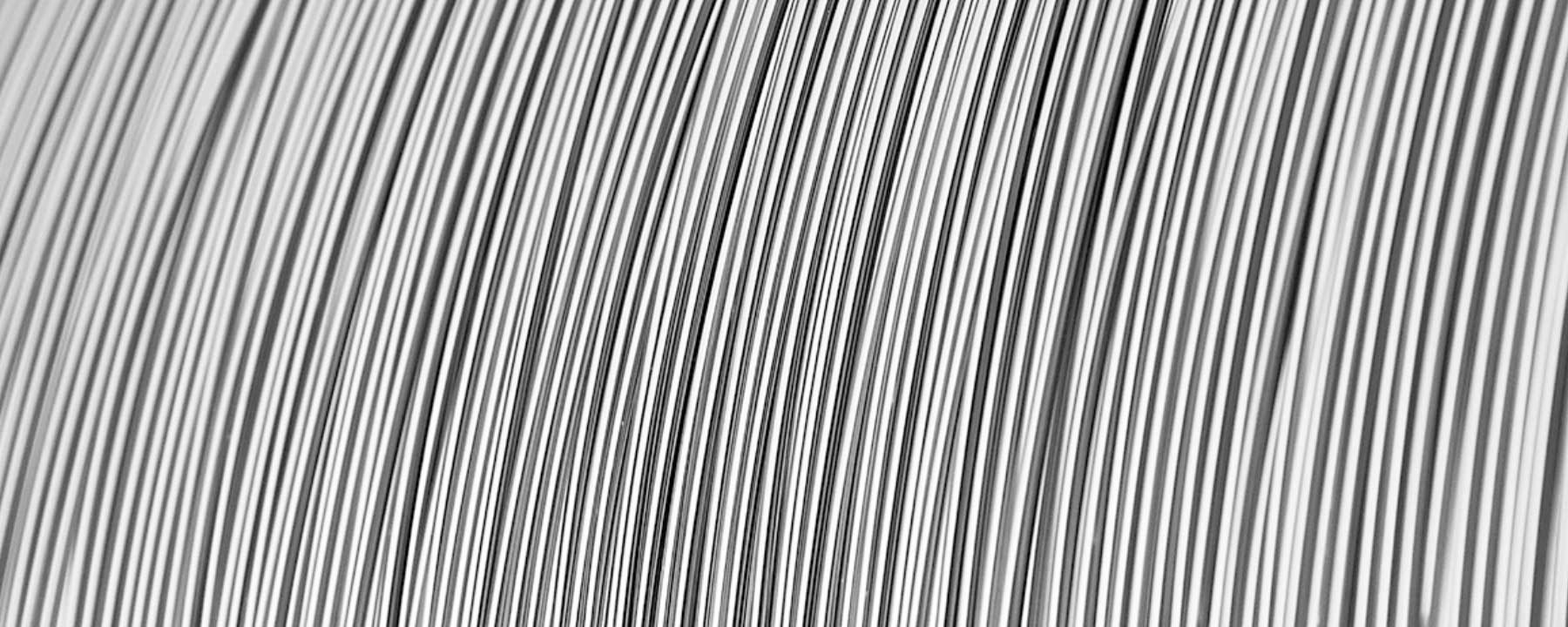

wire

Applications

Wire produced by Stahlrump is used in many special technical applications; these include the following specialty product areas:

- High-performance industrial needles

- Highly-stressed components in textile machinery

- Highly-loaded rolling elements

- Precision mechanical tools with long service lives

- Products for medical equipment

- Highly-loaded fasteners

- Drill bits, precision saws

- Precision turned parts

Size range

Diameter: 0.15 to 11.00 mm

Microstructure

According to Stahl-Eisen-Prüfblatt SEP 1520 and DIN EN ISO 643

Conditions

+ A (annealed)

+ AC (annealed and drawn)

+ C (drawn)

+ LC (slightly redrawn)

Tolerances

Standard tolerances to DIN EN 10218-2

Special tolerances upon request

Surface finishes

According to DIN EN 1653:

- SL (ground)

- SH (peeled)

- BK (bright)

- HEBK (special bright)

- special surfaces upon request

On request

Eddy current crack detection

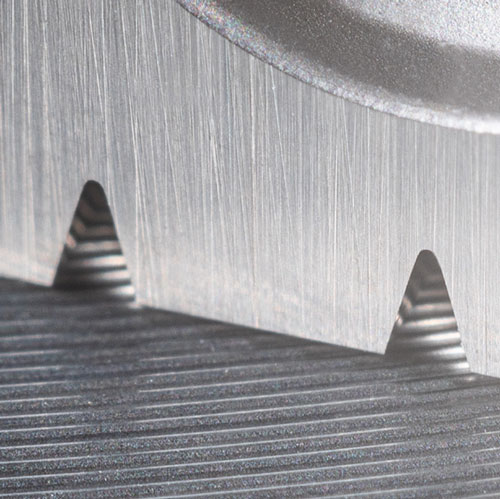

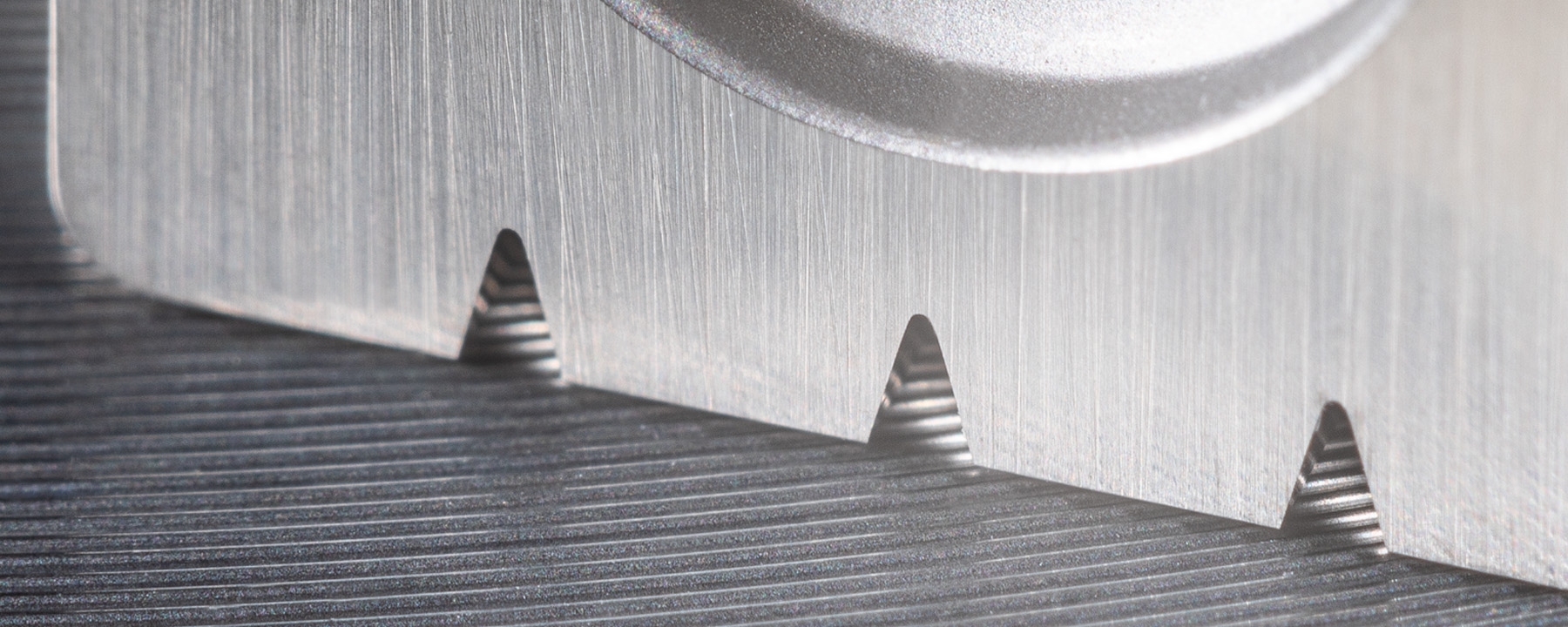

bright bar

Applications

Bars produced by Stahlrump are used in many special technical applications; these include the following specialty product sectors:

- Axles and shafts

- Locking pins

- Drill bits, cutters tools, files, hand tools

- Stamped parts for extremely demanding applications

- Precision-turned parts of all types

- Products for medical and dental devices

Size range

Standard 2.00 to 10.00 mm

Short pieces 2.00 bis 6.50 mm

Further dimensions possible upon request

Bar length

Standard 150 to 3000 mm

Short pieces 150 mm x wire diameter ascending

Further length possible upon request

Microstructure

According to Stahl-Eisen-Prüfblatt SEP 1520 and DIN EN ISO 6433

Conditions

+ A (annealed)

+ AC (annealed and drawn)

+ C (drawn)

+ SL (ground)

Tolerances

Standard tolerances to DIN EN 10278 (ISO 286-2 from h6)

Special tolerances upon request

Surface finishes

Standard surface finishes to DIN EN 10277-1 up to and including class 4

Special surface finishes possible upon request

On request

Chamfered

Eddy current crack detection from 2.50 mm diameter and upwards

Demagnetised

cold rolled strip

Applications

Cold rolled strip produced by Stahlrump is used in many special technical applications; these include the following specialty product areas:

- Textile needles for the most demanding industrial applications

- Sinkers for precision and mechanical engineering

- Precision parts for machine construction

- Products for the tool industry

- Precision mechanical engineering products

Size range

Thickness: 0.10 to 2.00 mm

Width: 5.00 to 340.00 mm

Coil diameters

Inside: 300, 400 or 500 mm

Outside: max. 1400 mm

Microstructure

According to Stahl-Eisen-Prüfblatt SEP 1520 and DIN EN ISO 643

Conditions

+ A (annealed)

+ AC (annealed, rerolled)

+ C (rolled)

+ LC (sligthly rerolled)

Surface finishes

According to DIN EN 10139:

Surface finishes MA, MB, MC in the versions:

- Rough

- Dull

- Smooth

- Bright

- Special surface finishes possible upon request

For stainless qualities to DIN EN 10088-2:

- 1 G (ground)

- 1 P (bright polished)

- 2 B (cold rerolled)

- 2 D (cold rolled, smooth)

- 2 H (hard rolled)

- Special surfaces upon request

Tolerances

Standard tolerances to DIN EN 10140

Special tolerances upon request

hardened and tempered strip

Applications

Hardened and tempered strip produced by Stahlrump is used in many special technical applications; these include the following specialty product areas:

- Weaving heddles and drop wires for textile machine construction

- Precision parts for precision and mechanical engineering

- Products for the tool industry

Size range

Material thickness: 0.20 to 0.39 mm; width up to 20 mm

Material thickness: 0.40 to 1.00 mm; width up to 40 mm

Conditions

+ QT (hardened and tempered)

Tolerances

Standard tolerances to DIN EN 9445-1

Special tolerances upon request

Surface finishes

According to DIN EN 10088-2

2 Q (bright hardened and tempered)

strip with rounded edges

Applications

our strip with rounded edges is used in many special technical applications; these include the following specialty product areas:

- reeds for textile machinery

- precision parts for mechanical engineering

- products for knife production

- precision mechanical engineering products

Size range

thickness: 0,10 – 0,8 mm

width: 3,00 – 30,00 mm

Conditions

for edges shaped by a cutting tool for cold-rolled strip:

- + AC (annealed, rerolled)

- + C (cold-rolled)

- + LC sligthly rerolled)

for hardened and tempered strip

- according to DIN EN 10088-2

- + QT (hardened and tempered)

Surface finishes

for carbon steels: Standard according to DIN EN 10139

for martensitic and austenitic grades in accordance with DIN EN 10088-2:

- 1 G (ground)

- 2 B (cold rerolled)

- 2 D (cold rolled, smooth)

- 2 H (hard rolled)

- 2Q (bright hardened and tempered)

Special finishes upon request

Tolerances

for cold-rolled strip:

- Standard according to DIN EN 10140

for martensitic and austenitic grades:

- Standard tolerances to DIN EN 9445-1

Special tolerances upon request

Delivery form

Coil:

- inner diameter: 400 mm / 500 mm

- outer diameter: max 900 mm

Spool:

On request